Structural Steel

In line with the commitment to quality, productivity and safe environment. Bansal Group’s Steel Rolling Mills are designed to ensure efficiency and operational safety. Bansal Group has 2 Rolling Mill Plants namely M/s Bansal Iron & Steel Rolling Mill and M/s Bansal Ispat Udyog with a total capacity of 2,50,000 Tons/Year.

Bansal Iron & Steel Rolling Mill

Bansal Iron & Steel Rolling Mill was successfully commissioned in 1975 to be the first modern steel constructed in India. The mill is 16’’ mill which is currently manufacturing Beams, Channels, Angles and H-Beams from 125 to 200 mm. This is one of the first rolling mills set up in India. This mill is equipped with a Gasifier for providing better Heat Treatment to the raw material.

Bansal Ispat Udyog – TMT & Structural Steel Mill

With the increasing demand for the TMT & Structural Steel. In 2010, Bansal Ispat Udyog was successfully commissioned state of the art automatic mill for production of TMT Bars under the famous brand name of “Kamdhenu Steel” and Structure Steel. The advance production unit is equipped with state-of-the-art plants equipped with CNC machines to handle the in house process of melting, casting, rolling and twisting. The well-equpped manufacturing unit ensures bulk products in minimal possible time. It also assists in customized product development. The facilities are based at Mandi Gobindgarh (Punjab) INDIA. Currently plant is producing TMT Bars (Kamdhenu Steel) from 8 mm To 32 mm and Structural Steel from 200 mm to 600 mm.

We deals in the following Structural Steel Products:

CHANNELS

We roll channel section and quality are equivalent to main steel plants. These channel section come in a wide array of applications. Our channel sections are supplied to govt. and other organizations all over India.

Our channel sections are available in sections ranging up to 300 X 100 mm

| Wt Kg / Per FT | Wt Kg / Per Mtr | Thickness | |||

|---|---|---|---|---|---|

| MC 125 X 65 | 129.125 | 65 | 3.800 | 12.468 | 6 |

| LC 125 X 65 | 123.124 | 63 | 3.000 | 9.843 | 4 |

| MC 150 X 75 | 149.15 | 73 | 4.900 | 16.077 | 5.5 |

| LC 150 X 75 | 149.15 | 71 | 4.200 | 13.780 | 5.5 |

| LC 175 X 75 | 174.75 | 72 | 4.800 | 15.749 | 5.5 |

| MC 200 X 75 | 200 | 74 | 6.800 | 22.311 | 7.5 |

| LC 200 X 75 | 199.2 | 73 | 5.700 | 18.702 | 6 |

| MC 250 X 80 | 250 | 80 | 10.42 | 34.2 | 7.5 |

| MC 300 X 90 | 300 | 90 | 11.1 | 36.3 | 7.8 |

| MC 400 X 100 | 400 | 100 | 15.3 | 50.1 | 8.8 |

* Bansal's Channels: 125mm to 300mm

As per IS: 2062-92 Grade'A'

Special Feature: Low temperature rolling imparts higher strength to the structures. Pilling and automatic tying of the structurally ensure minimum damage during handling and transport.

BEAMS / GIRDERS

Beams forms an essential part of every high and establishment. It is the primary Structure used in various set ups. Our Beams are perfectly elongated and undergo various strength determination test.

- Strengthened by state of the art Manufacturing process

- Internationally acceptable standards are maintained at all levels

- Size accuracy and weight uniformity is duly maintained

| Wt Kg / Per FT | Wt Kg / Per Mtr | Thickness | |||

|---|---|---|---|---|---|

| LB 125 | 124.25 | 60.61 | 1.900 | 6.234 | 3.5 |

| MB 150 | 149.150 | 74.75 | 4.300 | 14.108 | 5.5 |

| LB 150 | 149.150 | 73.74 | 3.700 | 12.140 | 4.5 |

| JB 150 | 149.150 | 69.70 | 3.300 | 10.827 | 4.0 |

| 149.150 | 68.69 | 2.800 | 9.187 | 3.5 | |

| 150.151 | 63.64 | 2.400 | 7.874 | 3.0 | |

| MB 175 | 174.750 | 84.85 | 5.500 | 18.046 | 5.5 |

| LB 175 | 172.730 | 78.80 | 4.700 | 15.421 | 5.0 |

| JB 175 | 166.670 | 73.74 | 3.700 | 12.140 | 4.0 |

| 163.640 | 65.66 | 2.900 | 9.515 | 3.5 | |

| MB 200 | 198.200 | 98.100 | 7.500 | 24.608 | 7.0 |

| LB 200 | 192.930 | 85.86 | 5.500 | 18.046 | 5.0 |

| JB 200 | 188.900 | 78.80 | 3.900 | 12.796 | 4.0 |

| MB 250 | 250.000 | 125.00 | 11.368 | 37.300 | 6.9 |

| MB 300 | 300.000 | 140.00 | 14.020 | 46.000 | 7.7 |

| MB 350 | 350.000 | 140.00 | 15.971 | 52.400 | 8.1 |

| MB 400 | 400.000 | 140.00 | 18.744 | 61.500 | 8.9 |

| MB 450 | 450.000 | 150.00 | 22.066 | 72.400 | 9.4 |

| MB 500 | 500.000 | 180.00 | 26.486 | 86.900 | 10.2 |

* Sizes Available: Beams: 125mm to 600mm

H-Beams: 100mm to 200mm

Section Column & Wide Flange Beams

We are manufacturing all high quality section column and wide flange beams with the finest raw materials. These sections are mainly used for railway, electrification etc.

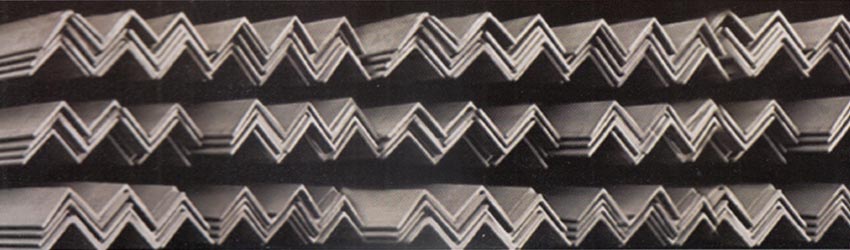

ANGLES

The range of our steel angles undergoes various processes before they are finally ready to be used.

These are available in the following specifications:

| Size (mm) | Sec. Wt. Kg/m | Sec. Area, a cm2 | D mm | B mm | T mm |

|---|---|---|---|---|---|

| 50X50X5 | 3.80 | 4.79 | 50 | 50 | 5 |

| 50X50X5 | 4.50 | 5.68 | 50 | 50 | 6 |

| 50X50X8 | 6.00 | 7.41 | 50 | 50 | 8 |

| 60X60X5 | 4.50 | 5.75 | 60 | 60 | 5 |

| 60X60X6 | 5.40 | 6.84 | 60 | 60 | 6 |

| 60X60X8 | 7.00 | 8.96 | 60 | 60 | 8 |

| 65X65X5 | 4.90 | 6.25 | 65 | 65 | 5 |

| 65X65X6 | 5.80 | 7.44 | 65 | 65 | 6 |

| 65X65X8 | 7.70 | 9.76 | 65 | 65 | 8 |

| 65X65X10 | 9.40 | 12.00 | 65 | 65 | 10 |

| 75X75X5 | 5.70 | 7.27 | 75 | 75 | 5 |

| 75X75X6 | 6.80 | 8.66 | 75 | 75 | 6 |

| 75X75X8 | 8.90 | 11.40 | 75 | 75 | 8 |

| 75X75X10 | 11.00 | 14.00 | 75 | 75 | 10 |

| 80X80X6 | 7.30 | 9.29 | 80 | 80 | 6 |

| 80X80X8 | 9.60 | 12.20 | 80 | 80 | 8 |

| 90X90X6 | 8.20 | 10.50 | 90 | 90 | 6 |

| 90X90X8 | 10.80 | 13.80 | 90 | 90 | 8 |

| 90X90X10 | 13.40 | 17.00 | 90 | 90 | 10 |

| 100X100X6 | 9.20 | 11.70 | 100 | 100 | 6 |

| 100X100X8 | 12.10 | 15.40 | 100 | 100 | 8 |

| 100X100X10 | 14.90 | 19.00 | 100 | 100 | 10 |

| 110X110X8 | 13.40 | 17.10 | 110 | 110 | 8 |

| 110X110X10 | 16.60 | 21.10 | 110 | 110 | 10 |

| 110X110X12 | 19.70 | 25.10 | 110 | 110 | 12 |

| 130X130X8 | 15.90 | 20.30 | 130 | 130 | 8 |

| 130X130X10 | 19.70 | 25.10 | 130 | 130 | 10 |

| 130X130X12 | 23.50 | 29.90 | 130 | 130 | 12 |

| 150X150X10 | 22.9 | 29.2 | 150 | 150 | 10 |

| 150X150X20 | 44.1 | 56.2 | 150 | 150 | 20 |

| 200X200X12 | 36.9 | 46.9 | 200 | 200 | 12 |

| 200X200X16 | 48.5 | 61.8 | 200 | 200 | 16 |

| 200X200X20 | 60 | 76.4 | 200 | 200 | 20 |

* Thickness: 5mm to 20mm

Size: 50 X 50mm to 200 X 200mm

Material: Mild Steel

Special Feature: Low temperature rolling imparts higher strength to the structures. Pilling and automatic tying of the structurally ensure minimum damage during handling and transport.

TMT BARS

We are an ISO 9001:2008 Certified Company engaged in manufacturing of TMT Bars under the brand name of KAMDHENU STEEL. Extensive expertise, hardwork, capable organisation & no compromises in quality has made our products in demand. We are a group that strongly belives in excellence and cutting-edge technical expertise, something we have always given prime importance to go matter what venture we undertake.

These are available in the following specifications:

| Mech. Parameter | IS : 1786 Fe 550 | KAMDHENU TMT Fe 550 D* | IS : 1786 Fe 500 | KAMDHENU TMT Fe 500 D* |

|---|---|---|---|---|

| Yield Strength (Min) | 550 N/mm2 | 575 N/mm2 | 500 N/mm2 | 540 N/mm2 |

| Tensile Strength (Min) | 585 N/mm2 | 650 N/mm2 | 565 N/mm2 | 600 N/mm2 |

| Elongation% (Min) | 8.00 | 12.00 | 16.00 | 18.00 |

| Chemical Comp.% | ||||

| Carbon | 0.30 | 0.14-0.22 | 0.250 Max | 0.25 Max |

| Sulphur | 0.055 Max | 0.050 Max | 0.040 Max | 0.035 Max |

| Phosphorous | 0.050 Max | 0.050 Max | 0.040 Max | 0.035 Max |

| S+P | 0.100 Max | 0.095 Max | 0.075 Max | 0.070 Max |

*(Typical Value for 90% Heats)

* Sizes: 8mm to 32mm

Grades: FE415, FE500, FE500D

Special Feature: Low temperature rolling imparts higher strength to the structures. Pilling and automatic tying of the structurally ensure minimum damage during handling and transport.